The COVID 19 pandemic disrupted manufacturing operations practically overnight, leaving many companies racing to adjust and make changes without a major impact to plant operations.

Manufacturers that invested in Industry 4.0 technologies prior to the pandemic had more flexibility and agility to adapt to the unplanned circumstances. But that doesn’t mean it’s too late for organizations that did not.

Automation Intellect’s cloud based software can be implemented in just days. The pre-built solution is focused on providing visibility into the plant floor in order to improve machine performance and profitability. Taking action now with the right technology will not only support business continuity today, it will help your organization quickly adapt to unknown variables of an outbreak such as COVID-19.

“Companies that have invested and continue to invest in cutting-edge capabilities that allow them to quickly respond to production changes often come through these difficult times strong and as industry leaders. These manufacturers are able to monitor their operations, in real-time and adjust their operations accordingly.” Smart Industry

Automation Intellect provides benefits for the unique challenges of a crisis and beyond:

The ability to support remote monitoring of plant operations.

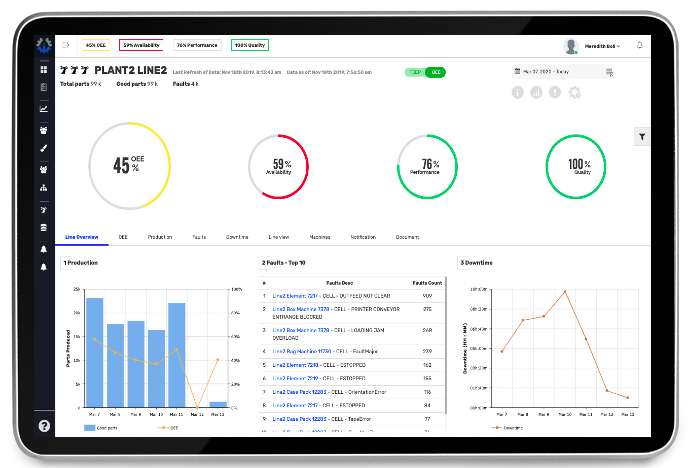

With social distancing, new safety measures and remote work environments now in place, it’s more important than ever to reduce manual processes and have remote access to machine data. Automation Intellect’s web-based software gives managers remote visibility into machine and plant performance. Gain real time insight into production, downtime, faults, and the financial impact of your OEE.

Insight into hidden capacity to get the most out of the equipment you have

Our Total Effective Equipment Performance, or TEEP feature shows manufacturers where and when there is untapped production capacity that can be utilized. Automation Intellect provides insight into both OEE and TEEP to make the data-driven decisions when planning and scheduling production.

Automated real time alerts to the right people at the right time

Fix problems as soon as they happen and minimize downtime. No more waiting until the end of a shift to realize there were issues or stoppages. Alerts identify underperforming machines immediately so issues can be addressed in real time.

Optimize resource allocation.

While some manufacturers are experiencing labor shortages, others are adding additional resources to accommodate higher demand. With Automation Intellect, you can make data driven decisions about where and when to shift labor and gain insight into high or low performing shifts.

Remote Access to Real-Time Data to Optimize Production Performance

To support a remote working environment, Automation Intellect gives managers the data they need to understand exactly what’s happening on the plant floor, without being present. They can make rapid recommendations to minimize bottlenecks and increase throughput.

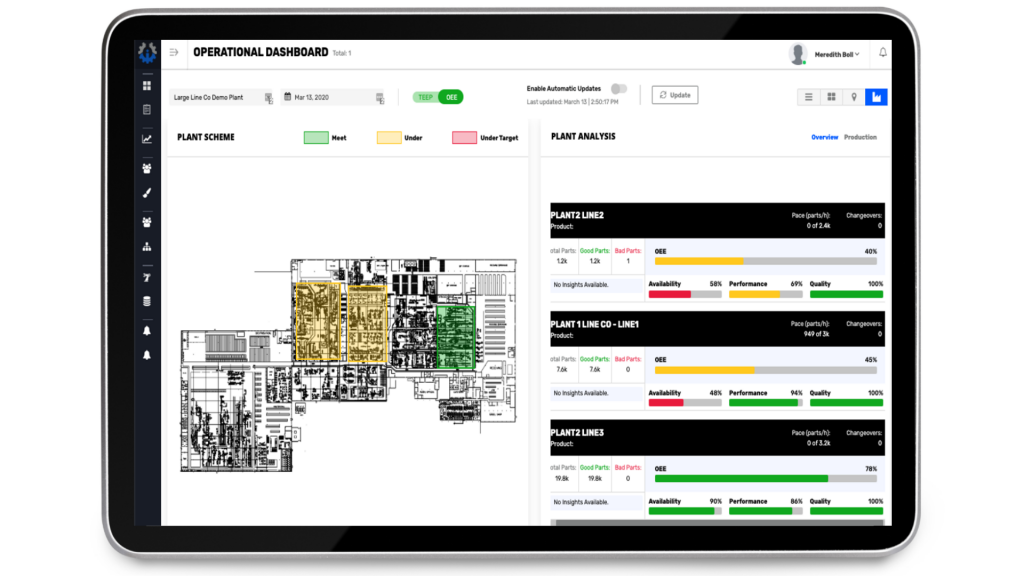

Automation Intellect’s Plant View gives users a quick snapshot of plant performance with visual insights into where they need to take action.

From there, managers can drill down to get granular level details for any line or machine. Find out which faults are causing the most costly downtime and understand the impact that microstops are having on output numbers.

Automation Intellect’s pre-built IIOT solution can be deployed in just days, and in most cases, implemented remotely. Our Customer Success Team handles all of the tag identification and configuration. Once deployed, our team of Lean Six Sigma experts trains your staff on how to maximize plant performance using insights from Automation Intellect (cost included in implementation).

The crisis we are facing is likely not going away anytime soon and adapting today can help you maintain the efficiency and profitability of your plants even in a challenging climate.