Remote working has become the new norm for many roles in manufacturing. The sudden shift has been a challenge for many organizations that have to quickly implement new processes.

Manufacturers that have the ability to remotely view plant operations have been able to shift to new work environments with little to no disruption.

Remote monitoring gives managers, engineers and production teams 24/7 visibility into overall plant operations, sources of unplanned downtime and process inefficiencies.

Automation Intellect’s IIOT software solution enables manufacturers to monitor operations without being present on the plant floor. Our solution delivers remote, real-time insight into plant performance from anywhere, on any device.

Proactively and Remotely Solve Issues Before They Impact Your Business

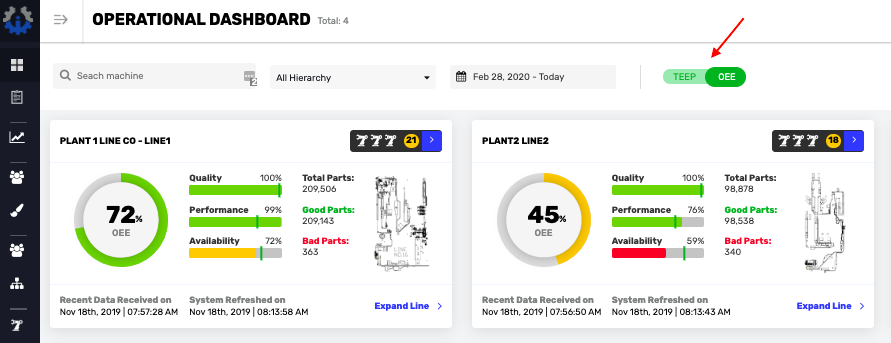

Automation Intellect is designed to improve machine performance, production output and plant efficiency, using OEE as a key metric.

Plant managers can get an overview of plant operations (screen on right) with visual alerting of OEE metrics to easily determine what lines or machines need attention.

Users can drill down to view metrics for each line and granular level production and downtime data for each machine. These insights allow plant leaders to take immediate action as well as visualize trends over time to prevent future downtime events.

Benefits of Remote Plant Monitoring:

Actionable Insights

Gaining real-time insight without having to be on the plant floor helps personnel make more informed decisions from any location.

Minimize Downtime

Remote monitoring ensures you have visibility into faults and unplanned downtime. With Automation Intellect, you can set up alerts and receive notifications by text or email when problems arise.

Better Manage Staffing

Automation Intellect allows users to remotely analyze machine and line performance by shift. If there is a need to move staff or production to a different line, managers have visibility into where resources should be deployed.

Reduce Manual Bottlenecks

Real time visibility and remote management of plant operations provided by Automation Intellect reduces the bottlenecks that occur from manual processes.

Get Up and Running in Days

Automation Intellect’s edge-drive infrastructure allows for a fast, low disruption implementation, with machine data visibility in just days. Our implementation can be completed remotely, with little to no onsite time required.

Remote functionality doesn’t end there. Our Customer Success Team is able to support clients on-site or off. With the ability to remotely support our customers, we can help them achieve maximum machine performance, drive continuous improvement and reduce issues when they arise.

“Taking action today to enable remote monitoring and other contingency plans will not only support business continuity today but help you become more resilient in the future.” Forbes

New Release – TEEP View

We recently rolled out TEEP view, or Total Effective Equipment Performance. TEEP is the measure of maximum available production time. With insight into OEE and TEEP (a simple toggle at the top of the screen!) manufacturers can understand the untapped capacity of their plants and the amount of additional production that can be unlocked without capital investment.

Get remote visibility into your plant’s performance in just days! CONTACT US TODAY to schedule an online demo of our software personalized for your manufacturing organization. You can also call us at 704-844-1806 or email at info@automationintellect.com