With 2024 just around the corner, manufacturers are gearing up to embrace a host of opportunities and challenges that lie ahead. At Automation Intellect, we’re committed to ensuring that you are well-prepared to thrive in this ever-evolving landscape. That’s why we’re here to provide manufacturers with a glimpse into the future by sharing the trends and predictions that will shape the industry in the coming year. Our team of over 25+ years of experience in manufacturing has made us a beacon of knowledge and a reference point in the world of IIoT for manufacturing.

The Current State of Manufacturing

Before we delve into the future, let’s take a moment to reflect on the present state of manufacturing. In recent years, the industry has witnessed remarkable advancements, with automation, digitization, and connectivity playing pivotal roles in driving efficiency and optimized production. Manufacturing processes have become increasingly data-driven, and the adoption of technologies like IIOT platforms, artificial intelligence (AI), and robotic equipment has become increasingly common.

However, alongside these advancements, manufacturers will face challenges. These include the need to manage vast amounts of data, ensure the security of interconnected systems, and adapt to changing consumer demands. As we turn our attention to 2024, these challenges are likely to persist, but so too are the opportunities for growth and competitiveness.

Now, let’s explore the trends and predictions that are set to define the manufacturing landscape in 2024:

Increased IIoT Integrations for Actionable Insights/Informed Decision-Making

Increased IIoT Integrations for Actionable Insights/Informed Decision-Making

In 2024, manufacturing leaders will continue to integrate IIoT platforms to gain real-time insights into their operations. IIoT sensors and data analytics platforms will empower leaders to monitor production processes, equipment performance, and quality control in real-time. These platforms will instantly relay data to a centralized dashboard accessible to plant floor leaders. With this data, leaders can detect anomalies, identify potential issues, and make data-driven decisions to optimize production processes. For example, they can adjust machine settings on the spot to prevent a potential breakdown, thus reducing downtime and ensuring consistent product quality. Manufacturers that invest in advanced IIoT platforms will gain a competitive edge.

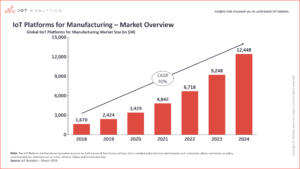

According to Forbes Enterprise Tech, Global spending on IIoT Platforms for Manufacturing is predicted to grow from $1.67B in 2018 to $12.44B in 2024, attaining a 40% compound annual growth rate (CAGR) in seven years.

.

Human-Centric IIoT Collaboration for Manufacturing Leaders

Human-Centric IIoT Collaboration for Manufacturing Leaders

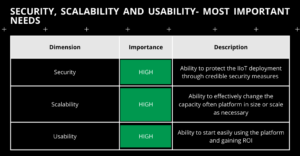

In 2024, the IIoT landscape will emphasize human-centric collaboration between manufacturing leaders and automation systems. IIoT solutions will be designed to enhance the capabilities of human workers on the factory floor – and leaders will play a pivotal role in this transformation by not only collaborating closely with these adaptable IIoT devices but also by coaching their teams in the effective use of these systems. It is of high importance for manufacturing leaders to be confident in the usability, scalability, and security of these IIoT platforms.

Agile IIoT-Enabled Production Adaptability

Agile IIoT-Enabled Production Adaptability

In 2024, IIoT will enable agile production line reconfiguration. Suppose a food processing plant produces various products, including different types of sauces. Through IIoT-enabled machinery and conveyors, leaders can quickly reconfigure the production line to switch from bottling one sauce to another. IIoT sensors will monitor inventory levels of raw materials and product demand in real-time. When the IIoT system detects a shift in demand, it will automatically adjust the production line’s settings. Plant floor leaders can oversee and approve these adjustments, ensuring that production adapts to changing market needs efficiently.

“IIoT platforms are beginning to replace MES and related applications, including production maintenance, quality, and inventory management, which are a mix of Information Technology (IT) and Operations Technology (OT) technologies” – Forbes Enterprise Tech.

Sustainability Leadership Through IIoT

Sustainability Leadership Through IIoT

In 2024, plant floor leaders will elevate sustainability to new heights with the integration of IIoT and AI. Imagine a scenario where your integrated IIoT platform not only monitors energy consumption but also can detect excessive energy waste and even track and measure abstract data points. When such inefficiencies are identified, the IIoT system promptly notifies leaders on the plant floor – prompting action and thus saving money. Organizations that prioritize sustainability and green IoT can benefit from reduced costs, improved brand image, and increased market share.

Automation Intellect stands out from competitors because we have the ability to track abstract data points, further enhancing sustainability efforts within manufacturing operations.

Sappi, a leader in the paper industry, has reduced its carbon dioxide emissions by 230,000 tons per year by leveraging IIoT solution.

Info via Sappi

Decision Support via IIoT

Decision Support via IIoT

IIoT platforms will offer valuable decision support to plant floor leaders, and it’s algorithms will analyze data and predict when specific machines may require maintenance. If an AI-powered system identifies an upcoming issue, it will notify plant floor leaders, who can then schedule preventive maintenance. This proactive approach prevents costly equipment breakdowns and minimizes production downtime, ultimately boosting operational efficiency. This will also continue to make the decision-making process a bit more manageable for plant floor leaders.

Automation Intellect stands out from it’s competitors because we further enhance this decision making process for your team leaders by providing you with a customer success specialist along the way. For a practical example of this, you can explore our case study here, showcasing how our specialists have empowered packaging manufacturers to make those timely decisions.

How to prepare? Here’s some helpful tips:

- Assess Your IIoT Readiness: Begin by evaluating your current IIoT capabilities and infrastructure. Identify specific areas where IIoT integration can improve efficiency and decision-making.

- Explore IIoT Solutions: Research IIoT platforms and solutions that align with your manufacturing needs. Look for providers like Automation Intellect that offer dedicated Customer Success Specialists.

- Invest in Team Training: Ensure your team is equipped to make the most of IIoT technology by investing in training and upskilling. Proficiency in IIoT systems is key to harnessing their full potential.

The future of industrial automation in 2024 is filled with new levels of opportunity. To thrive in this dynamic landscape, manufacturers need a guide, a partner, and a source of knowledge. Automation Intellect is all of that and more. Connect with us today to unlock the future of manufacturing.