Downtime and production losses are something every manufacturer experiences. The good news is, technology solutions are available that dramatically reduce the main sources of revenue loss: Unplanned Downtime, Minor Stoppages and Changeover Time.

When these solutions are implemented, manufacturers quickly realize how much time and revenue is lost with traditional strategies that are manual, time consuming and ineffective.

Based on more than 25 years of experience in manufacturing, we’ve outlined the top 3 profit killers in the industry and how they can be avoided.

1. Minor Stoppages

Minor stoppages are typically the most hidden factors of profit loss with dramatically more impact on downtime and revenue than manufacturers realize.

Traditional manual, paper-based systems rarely capture minor stoppages and the data is often unreliable.

IIOT technology solutions like Automation Intellect capture every fault and downtime event and the root cause of each stoppage.

Example

A packaging manufacturer was manually tracking stoppages but only capturing unplanned downtime that lasted 5 minutes or more.

The manufacturer implemented Automation Intellect’s IIOT platform to gain real-time visibility into machine level performance, including all stoppages.

In just one week, Automation Intellect identified micro stops that totaled a cumulative 7 hours. These were unplanned stops that were previously not recorded. The platform also alerted operators at the time of each stoppage so problems could be fixed as they happened.

2. Unplanned Downtime

Downtime is the largest source of lost production time and revenue. Yet, it’s estimated 80% of manufacturers are unable to accurately calculate their downtime or understand the costs associated with lost production.

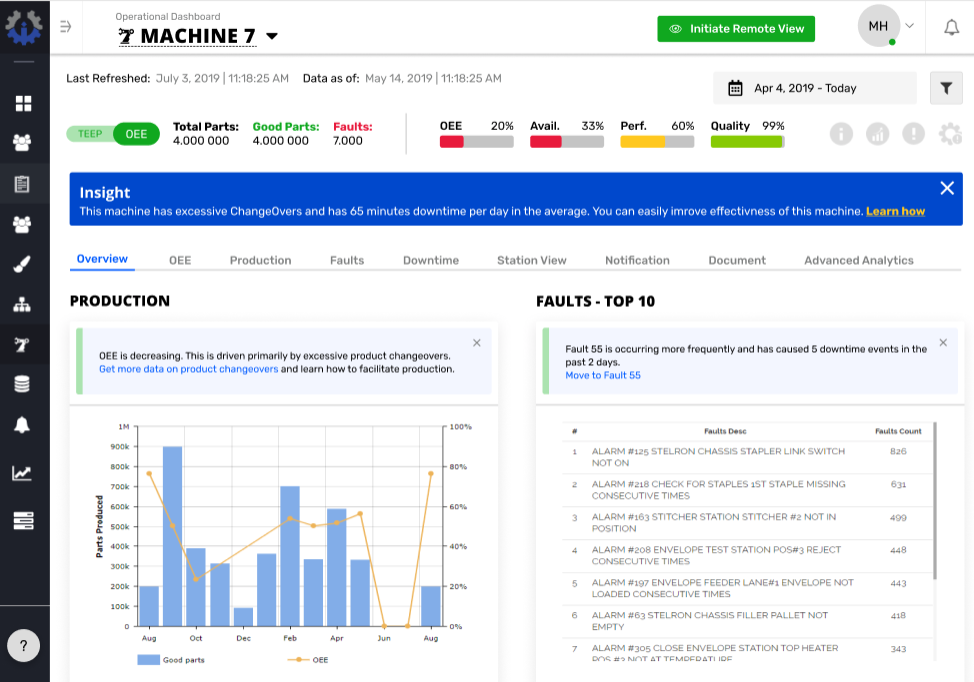

Automation Intellect provides real-time insight into the source of unplanned downtime including which machines have the most occurring faults and the highest aggregated amount of downtime.

Example

Managers at a tier one automotive manufacturer knew they had production and downtime issues but didn’t have visibility into the root cause of downtime events.

Insights from Automation Intellect identified the source of production issues so they could understand where and how to improve performance. The result was a 30% reduction in downtime and $250K in additional annual revenue.

3. Changeover Time

Changeover time accounts for the largest source of overall downtime. Yet, most manufacturers have little insight into how long changeovers take or what they can do to reduce changeover time.

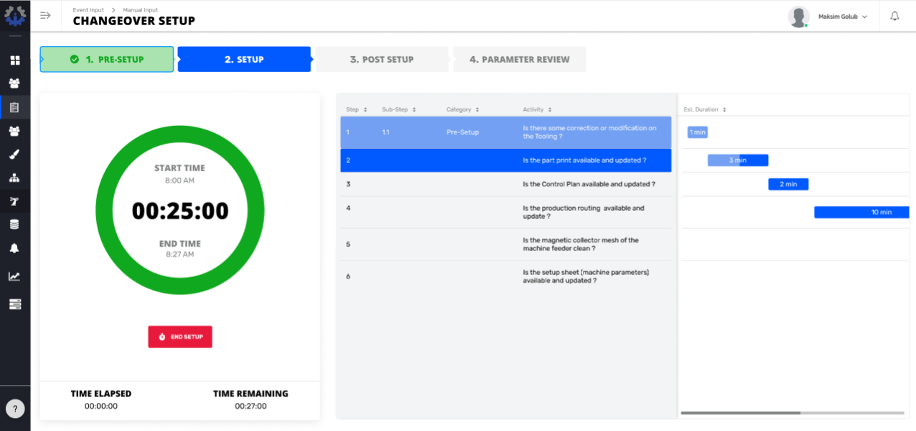

A SMED initiative (Single Minute Exchange of Dies) is the standard technique for analyzing and reducing the time it takes to complete equipment changeovers. Most SMED initiatives are manual projects, using excel spreadsheets and stopwatches.

Automation Intellect’s IIOT platform includes a SMED module that automates the SMED process and accelerates cost savings.

Example

A global manufacturer only analyzed changeover time and activities an average of once per year because it was such a time consuming and tedious process. In addition, their initiatives lacked a systematic way to collect and compare data to their benchmark changeover times.

Cost savings projections for this manufacturing client utilizing the Automation Intellect’s SMED module amount to $365K in one year. The projection is based on reducing the time of 8 changeovers on one line by just 5 minutes. Changeover reduction time is expected to exceed 5 minutes so the final cost savings numbers could potentially be much higher.

Are you ready to put a stop to the profit killers in your manufacturing organization? It’s easier than you think. Rapid implementation of Automation Intellect’s pre-built solution means you’ll have visibility into your plant, line and machine data in just days!