Reduce Changeover Time and Increase Revenue

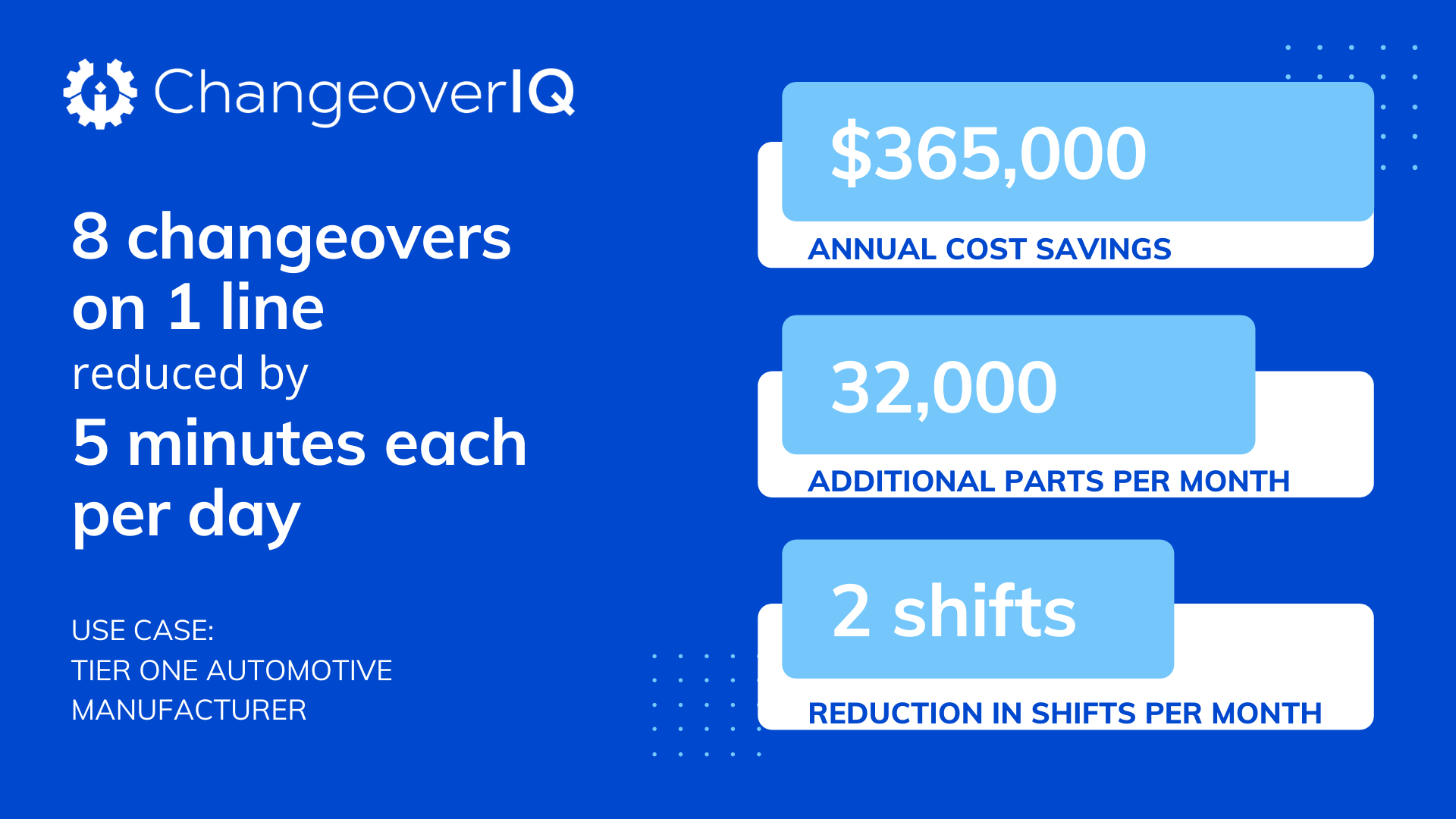

Changeover time is a hidden, yet significant cost for most manufacturers. The cost of changeover on just one line can run as high as 750K so there is considerable savings to be gained by reducing changeover downtime.

Automation Intellect has developed ChangeoverIQ, a first-of-its-kind module designed to accelerate SMED initiatives and allow manufacturers to produce more in less time.

Gain real-time visibility into changeover events on your plant floor so you can set goals and make improvements quickly.

ChangeoverIQ replaces the manual, time consuming process of evaluating changeovers with spreadsheets and stopwatches. It also accelerates continuous improvement initiatives with the ability to execute a detailed, digital SMED audit at any time.

The real client example below illustrates the significant savings that can be achieved. You can see the cost savings and productivity impact by reducing 8 daily changeovers by just 5 minutes each.

The most profitable benefits of improving changeover performance are reducing downtime and increasing machine utilization. However, the advantages extend beyond that, including:

-

Increase capacity and avoid CAPEX spend on new equipment

-

Improve the efficiency of your production schedule by shortening the combination of changeovers

-

Lower manufacturing costs

-

Reduce lead times and improve responsiveness to customers

Getting Started with ChangeoverIQ is easy. Your team will also be assigned a Customer Success Coach to get your changeover data loaded and ready to use.

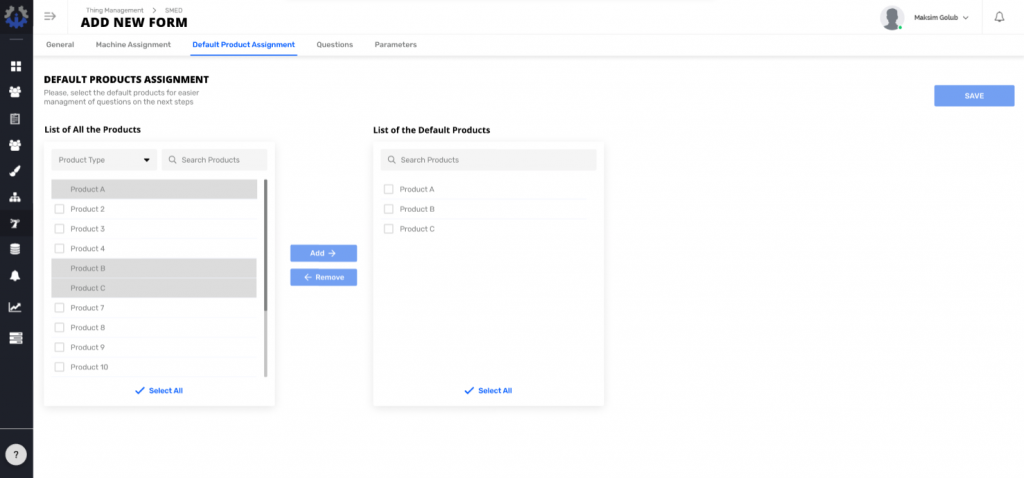

1) Changeover procedures are loaded

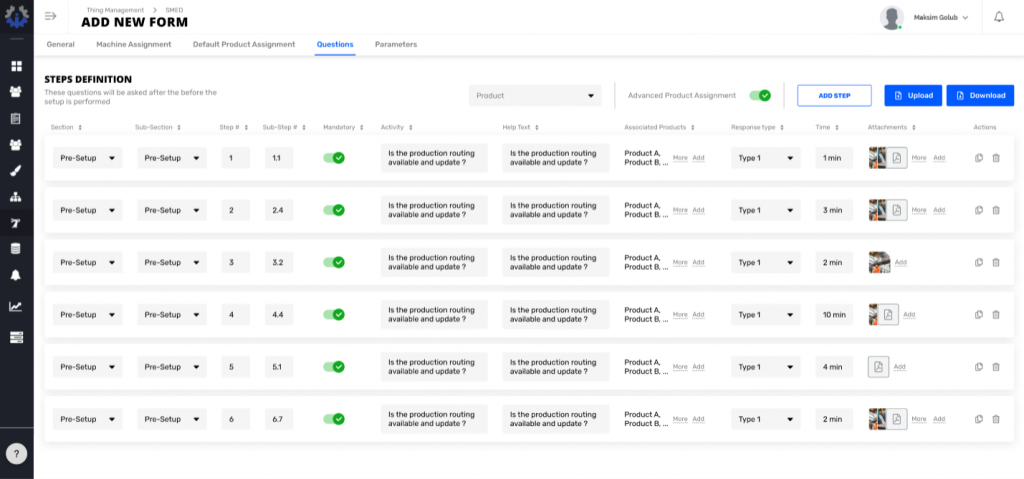

In the front-end administrative portion of the module, users build a customized Changeover process including the machines and products associated with each changeover. If you have this information in an excel spreadsheet, it can simply be imported.

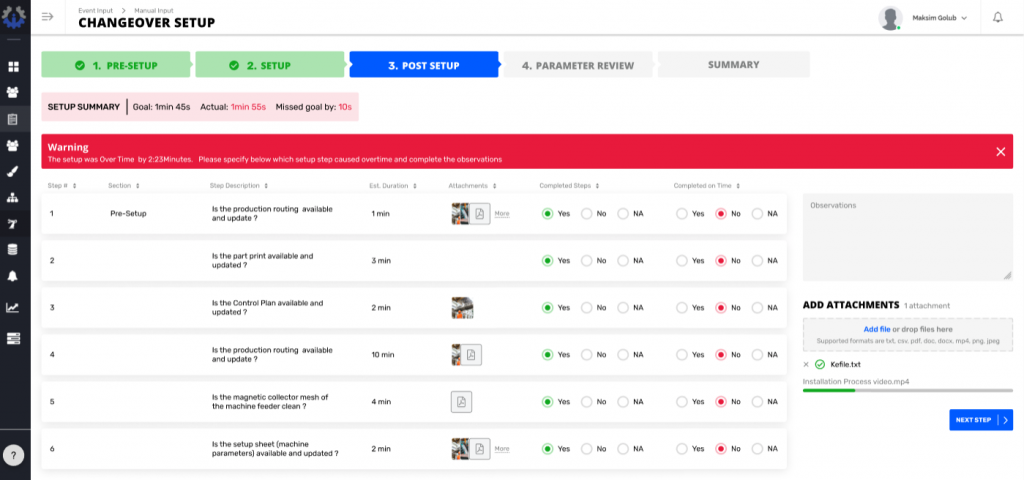

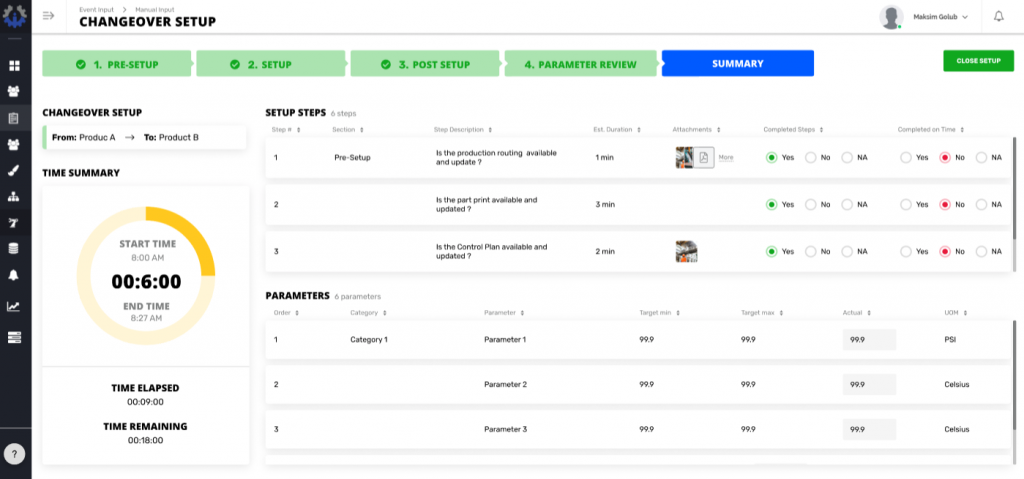

Next, the steps or activities for the changeover process are defined, including tasks that are performed before and after the line is shut down.

2) Changeovers are run and performance data is gathered

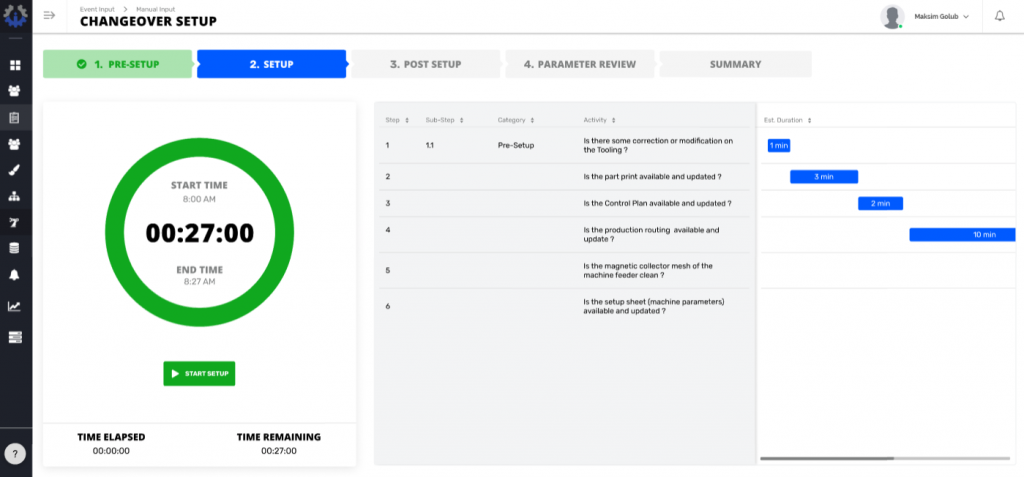

When the operator indicates a changeover has started, a timer in ChangeoverIQ begins. The task that should be complete in that timeframe is highlighted for the operator.

Once the changeover information is loaded, performance data can be gathered. These statistics will indicate how fast a changeover has been performed.

When the changeover is complete, the operator records any observations during the process, including tasks that took longer than expected or suggestions for improvement.

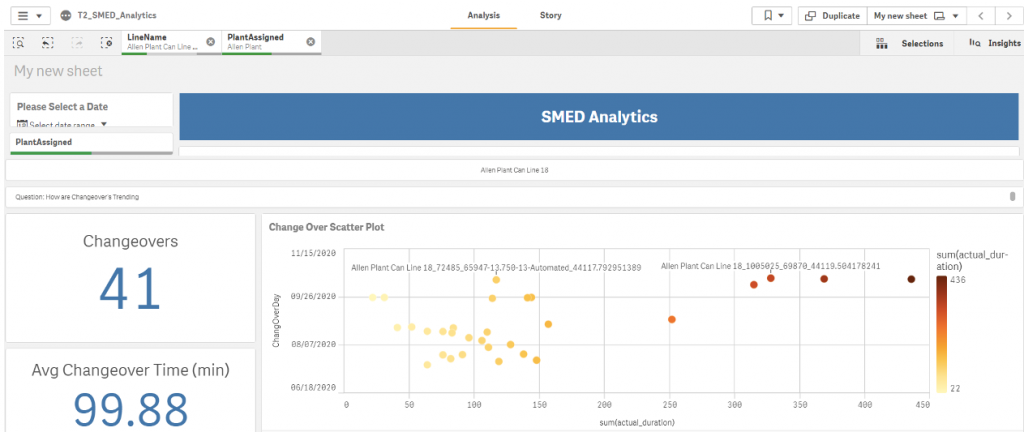

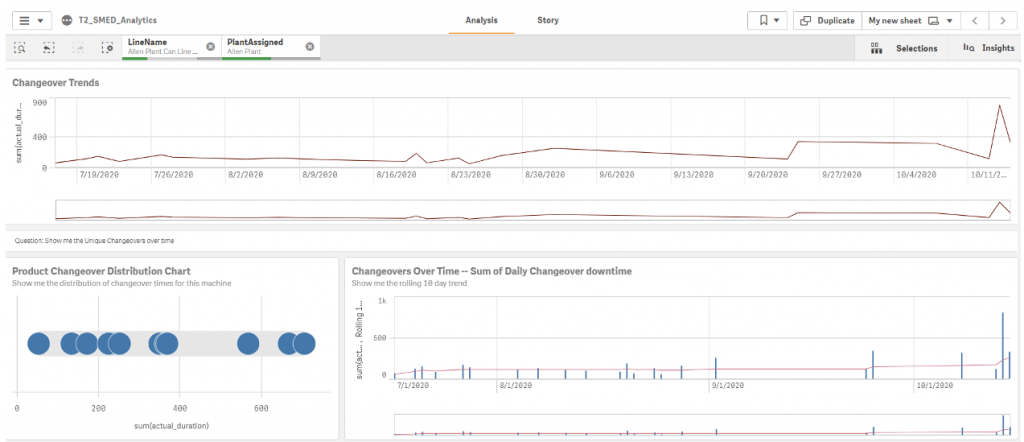

3) Analytics dashboard shows improvements and areas of concern

The analytics dashboard will give plant leaders a visual representation of changeover statistics. It’s a big picture view of how changeovers are improving and if any are out of range.

The dashboard shows managers how changeovers are trending over time as well as the worst performing lines or products so efforts can be focused on lines that need most improvement.

Are you ready to move from excel spreadsheets and stopwatches to analyze changeovers?

Gain real-time visibility into accurate changeover times by recording events across your plant floor. With ongoing visibility and recording of changeover processes you can make significant improvements that drive revenue and cost savings.