Following new safety measures designed to protect plant employees, Automation Intellect is pleased to offer complete remote installation of our software.

Implementing Automation Intellect is a rapid, low disruption process that can be completed in just days.

Our Remote Implementation starts with a virtual evaluation of your equipment so we can determine the hardware required to connect.

You’ll then receive our Implementation Kit which includes the edge connectivity devices that connect to your PLCs, a bus connector and an ethernet patch cable. We include instructions and support on how to connect the edge device to the PLC.

Once the edge device is installed in your panel, the Automation Intellect Customer Success Team handles the rest! We’ll connect to the edge device, and configure it for our software, using HMI and PLC information provided by your team.

Most customers go from connectivity to data visualization in just a day or two! Training by our Customer Success Team is included in implementation. Training includes how to navigate and use the Automation Intellect platform, as well as how to optimize data insights in order to improve plant performance, reduce unplanned downtime and increase throughput.

How Automation Intellect is Supporting Manufacturers During the COVID-19 Pandemic

The COVID-19 pandemic presents a challenge for manufacturers who are trying to reduce the number of employees on the plant floor while maintaining operations.

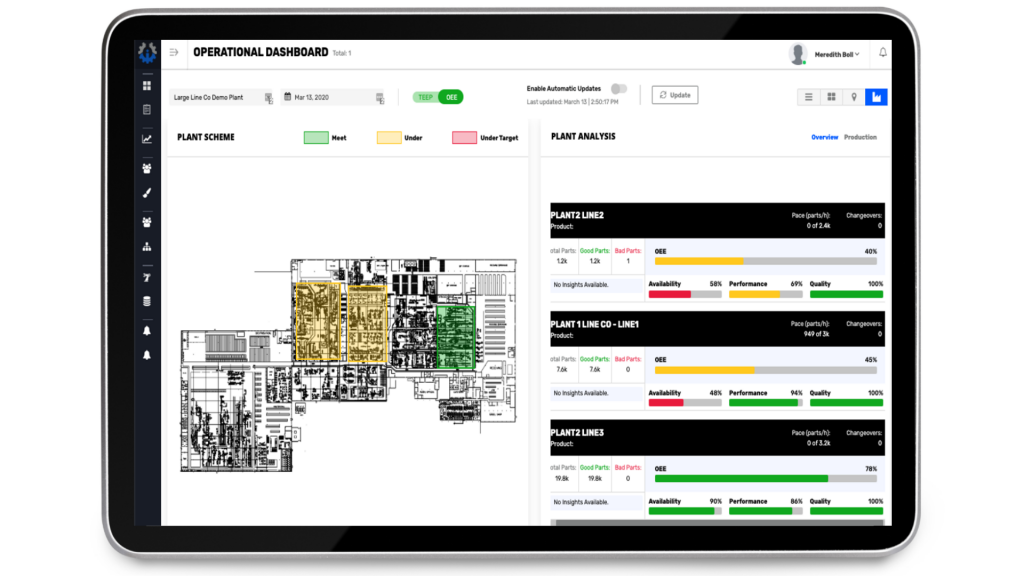

To support employees who have been shifted to working remote, Automation Intellect’s cloud-based software can be accessed anytime, anywhere from any device. This allows managers to gain remote visibility into plant performance, from a high level plant view (pictured below) down to a deep dive of every machine in the plant.

We’ve also introduced our Virtual Manager Module which further connects managers to the plant floor and employees, virtually! The module includes Remote View, which gives managers a secure, live video stream of a machine or line. It also includes Virtual Support, which allows team members to hold virtual meetings on the fly when issues arise.

Economic uncertainty caused by COVID-19 also has manufacturers looking for ways to reduce costs and improve efficiencies. Automation Intellect’s IIOT platform is built to help manufacturers achieve those goals with the following value added benefits:

Fix Downtime Problems as they Happen

Eliminate Time Consuming Manual Reporting

Improve Overall Equipment Effectiveness

Maximize Available Production Time with Insight into Capacity

Standing apart in the field of IIOT solution providers, Automation Intellect distinguished itself by demonstrating value early on, in ways that brought us critical insights into where and how we can improve.

Kurt Sharbaugh, IIOT Manager, Mann + Hummel