Industry 4.0 brings profound business and operational changes to manufacturing, driving new opportunities through advanced technologies. But is manufacturing ready? We did some research into what businesses are doing to position themselves for the next generation, and this is what we found.

Getting Ready

As leaders struggle to develop effective strategies for moving to Industry 4.0, several best practices tips are emerging to help with the transformation. Sources such as Bernd Gross, Industry 4.0 pioneer and thought leader, offer real-world guidelines:

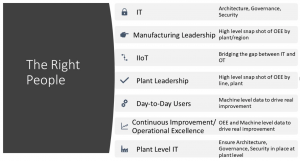

- Start fast, finish strong. In a world where a company’s strategic goals change quickly, projects need to show results fast. That demands the upfront involvement of the right mix of stakeholders who can develop a compelling proof of concept and minimum viable outcomes to support it. Establishing the right team will make it easier to move quickly with new technologies and implement an approach and a plan that works for the entire organization.

- Focus on Improving Process for Short-term ROI Gains. For example, a crucial foundation of the Smart Factory concept of Industry 4.0 is the ability to use OEE (overall equipment effectiveness) analytics to drive continuous improvement and quality management on the shop floor. When production is operating at optimum levels, with machine level data and OEE analysis, it delivers short-term savings directly to the bottom line. Reduced downtime (planned and unplanned), less scrap or waste, and increased throughput can all be translated directly into dollars and changes the way manufacturing approaches machine management.

- Take a Big Picture “Interoperability” Approach. Remember, the biggest impact of Industry 4.0 and the Industrial Internet of Things (IIoT) is in a highly integrated manufacturing network. Many of the technologies employed in today’s manufacturing environment are implemented separately but when looked at collectively, are the basis of the physical and virtual world of Industry 4.0, the future of manufacturing. Digitally connected departments and stakeholders use this disparate technology to manage both the business and production layers of the company, including manufacturing, order processing, fulfillment, product quality, and supply chain management. With the silos of information found in ERP, MES, OEE, and other business apps, a big picture 4.0 approach means taking into account open platform architectures, with multi-vendor and multi-protocol strategies and the highest security standards.

Factory of the Future

The digital revolution in the manufacturing industry will make the “smart factory” a reality that is not only efficient but agile and lean. Connecting the production team digitally with the business team will in turn, enable collaboration, shared data resources, and communications, resulting in better functionality across the entire enterprise. The technology is already here or on the way – and the smart business is already preparing for its arrival.

To find out more about Industry 4.0, the future of manufacturing, and how to prepare for it, request a demo of Automation Intellect today.